"Arsenic is colorless, odorless and tasteless, as well as toxic for humans even in small quantities. This element is naturally present in the soil and is liberated into ground water sources. In many regions of the world, millions of people drink water laced with arsenic and use it to irrigate their rice and wheat crops, which they later ingest. In early stages, arsenic poisoning causes skin lesions. As the arsenic accumulates within the body, the symptoms get worse: neurological damage, heart disease and cancer can result from continued exposure.

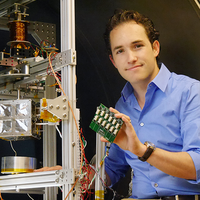

To overcome this silent, global threat, the engineer Margaret Lengerich has created a system that eliminates arsenic from water supplies cheaply and effectively. In contrast with other existing technologies, Lengrerich´s doesn´t use chemicals to filter the arsenic and doesn´t require the element which separates the poison from the water to be replaced for five years, she explains. This innovative approach has lead to Lengerich´s recognition as one of MIT Technology Review, Spanish Edition´s Innovators Under 35 Chile 2016.

Lengerich discovered this system, conceived by professor Joseph Calo from Brown University (USA) while completing her postgraduate degree in Innovation Management. The young engineer decided to perfect the technology and take it to market, and to this end she founded the company HMSolution in 2014.

Lengerich improved the system, registered a patent and designed and tested several prototypes. The current prototype is comprised by a 155 liter tank that processes 19 liters of water per minute. Well water is pumped into the tank where it is exposed to what Lengerich calls ""a filtering medium generator"". This medium is comprised of ""a wide variety of iron oxides that the system delivers"" within the tank. The iron oxides adhere to two chemical forms of arsenic: arsenic 3 and arsenic 5.

Lengerich explains that her system can directly filter both forms, unlike other systems which, in order to capture arsenic 3 need to pretreat the water with chlorine before exposing it to the filtering medium. Once the arsenic has been trapped, the oxide particles suspended in the water are directed through a pipe where they are trapped by a low cost filter. This system also captures other harmful elements, like aluminum, uranium and lead.

The World Health Organization´s quality standards for drinking water set the maximum concentration of arsenic per million parts of water at 0.01 milligrams or, in other words, 0.01 parts of arsenic per million parts of water. Lengerich says her system filters arsenic to the degree that it is undetectable, ""less than two parts per billion"".

In comparison with other existing technologies, HMSolution´s proposal is also more affordable. One of their systems with a treatment capacity of 76 liters per minute to supply drinking water to 250 people would cost between 3,400 and 4,500 euros, according to Lengerich. ""The competition offers them for between 4,000 and 6,000 euros, and they require a chlorine dosage system which adds another 4,500 euros to the total cost"", she explains. The operational and maintenance costs over 10 years would rise to 32,000 euros, ""approximately half of the costs associated with competing systems.""

Although HMSolutions has plans to build a pilot plant in Chile, for now they have detected a market opportunity in the United States, a country which ""is initiating a process to modernize their water infrastructure and create new wells and treatment systems to serve rural communities"", Lengerich explains. In areas like New Hampshire, 40% of the population relies on groundwater, and since the residential market is not regulated, many people do not treat the water, leading to arsenic exposure. In existing wells, HMSolution could ""easily convert the existing storage tanks into treatment tanks,"" she says.

During the next few months, the company will install their first system in an elementary school in Harvard, Massachusetts (USA), a rural area where the water supply relies on wells that are contaminated with arsenic. Later, with a greater processing capacity, they could serve larger communities. To supply water to 3,000 residents, the company estimates that they would need to install four 2,800 liter tanks, with a 15 liter per second processing capability."