"The wind that blows over European seas generates, on average, 1% of the electricity consumed on the continent thanks the to 8 Gigawatts (GW) of power installed in coastal wind farms according to the 2014 data provided by the European Wind Power Association. This may not seem important, but it becomes significant when compared with the plans announced by industry leaders: to reach 10 GW in 2015 and to multiply these numbers by 10 in the near future. The technology developed by Yves van Ingelgem may prove crucial in reaching this ambitious goal.

The turbines located in wind farms are steel giants with feet of clay. Because their foundations are under water, the steel that supports the structures is especially vulnerable to the corrosive power of the waves. The combination of water, salt and oxygen is lethal for this material, making it of vital importance to remain in touch with the condition of the metal in order to avoid irreparable damage to these megastructures.

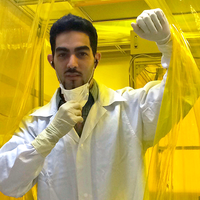

This is exactly what Zensor, the company founded by this Belgian innovator, provides using sensors which detect alterations in the materials long before they can compromise the integrity of these structures. The company installs an array of different sensors, which then regularly measure multiple aspects related to the state-of-health of the materials. Zensor then introduces the data collected into the analysis software designed by Van Ingelgem himself to produce a final diagnosis.

It all began coincidentally while Van Ingelgem was working on his doctorate in engineering at the Free University of Brussels (VUB, Belgium), where he developed algorithms used to analyze the reaction of metals to corrosion. When the material scientists began using his program they occasionally received unexpected results. Van Ingelgem recalls being told that his algorithms were faulty, however it was later shown to be just the opposite. The analysis produced by his software using the measurements obtained by the researchers proved to be capable of identifying the metal dissolution reaction at earlier stages than the traditional methods used previously.

As the CEO of Zensor explains regarding the way his sensors work: “Instead of measuring the loss of material as result of corrosion, we measure the activity generated by the corrosive reaction itself as we study the variation of the electrical response of the metallic surface”. In this way it is possible to continuously measure the condition of the structure´s materials, which allows the loss of structural integrity to be detected much earlier than it could be identified via inspection processes.

The financial benefits for companies that adopt Van Ingelgem´s technology are numerous. Early detection reduces maintenance costs since the necessary repairs are both simpler and less expensive than those required by issues which have advanced further. Improved maintenance also prolongs the lifespan of these structures, rendering them even more cost effective, and improved quality control minimizes the risk of accidents which in turn reduces insurance premiums.

Where coastal wind farms are concerned these all contribute to reducing the price of the electricity generated, increasing the viability of this energy source. Today Zensor´s technology is already being used at two such coastal wind farms, with a third installation already underway and several more in the pipeline for installation soon.

For the Director of the National Scientific Institute of Quebec and jury member for the MIT Technology Review Innovators Under 35 Belgium Federico Rosei, “the technology developed by Yves van Ingelgem is very promising, it proves not only a masterful grasp of engineering but also potential relevance for the field”."