Lithium-ion batteries are now widely adopted by manmade applications. Countless electronic products depend on lithium-ion batteries as their energy source. However, the capacity of lithium-ion batteries has been plagued by the problem of “rocking chair batteries”.

When discharging, lithium ions move from the anode (through the external circuit) to the cathode, and when charging, the ions move back from the cathode (through the electrolyte) to the anode. This back and forth process is like a rocking chair, hence the name. However, during the initial charge and discharge cycle, the cathode will consume a small amount of the lithium ions (usually about 10%), meaning the lithium ions that eventually return to the anode are reduced, thus reducing the actual capacity and energy density of the battery.

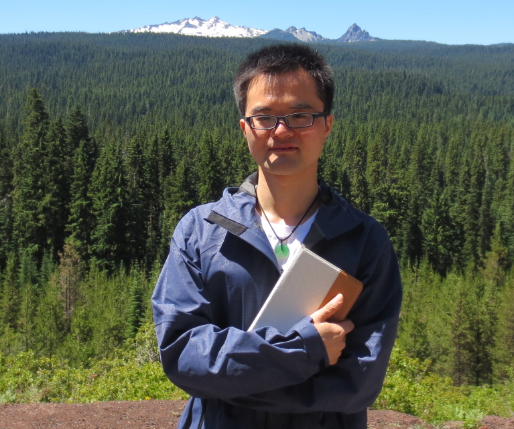

Wanting to find a solution to this problem, Yongming Sun - Professor at Huazhong University of Science and Technology’s Wuhan National Laboratory for Optoelectronics - developed a new lithium compensation additive material for lithium-ion battery anodes. This material is a class of nanocomposites composed of ultrafine nano-metal particles and lithium compounds (Li2O, LiF and Li2S), which can effectively compensate for active lithium loss during the first charge-discharge cycle of a lithium-ion battery. In testing, the addition of a 4.8% Li2O / Co composite material to the LiFePO4 anode resulted in an 11% increase in the battery capacity.

Compared to traditional lithium-rich compounds as anode lithium compensation materials, this type of material’s “donate-able” specific capacity more than doubled. While compared to cathode lithium compensation materials, this type of material has a high chemical and environmental stability. Along with a good fit into the industrial lithium-ion battery manufacturing process, this material has huge application potential in the lithium-ion battery industry.

In addition to the new lithium compensation material, Yongming also achieved a breakthrough in cathode materials for stretchable lithium-ion batteries. Using self-healing polymer’s mechanical stretchability and the ability to improve silicon cathode material’s charge and discharge stability, he designed and developed a stretchable carbon/silicon composite cathode material. Compared to conventional cathode material (lithium titanate), this material has more than 3 times the specific capacity, excellent charge and discharge stability (capacity retention rate of 81% at 100 cycles) , and mechanical properties (up to 88% over original size). Its relatively low negative working voltage also means an increase to the overall energy density of the battery.

As global energy and environmental challenges become ever more serious, fossil-fuel powered vehicles are bound to give way to electrical vehicles that use batteries as their power source. Smart grids and large-scale energy storage technologies will also require batteries. The focus of Yongming’s research - Lithium-based rechargeable batteries - are ideal for high-capacity, high-power energy storage applications. They are also a source of hope for a greener, cleaner future.